6 Axis MIG MAG Welding Robot Range 1500mm With Welding Machine

Characteristics

-Robot arm:

- Die casting process, aluminum arm ,Lighter and more flexible

- Internal wires and terminals of the robot are made by the top world famous brands: DYEDEN, TAIYO, the same as ABB and Fanuc

- Top Chinese brand of the controller,motor and reducer.

BR-1510 MIG welding robot parameters shows as below:

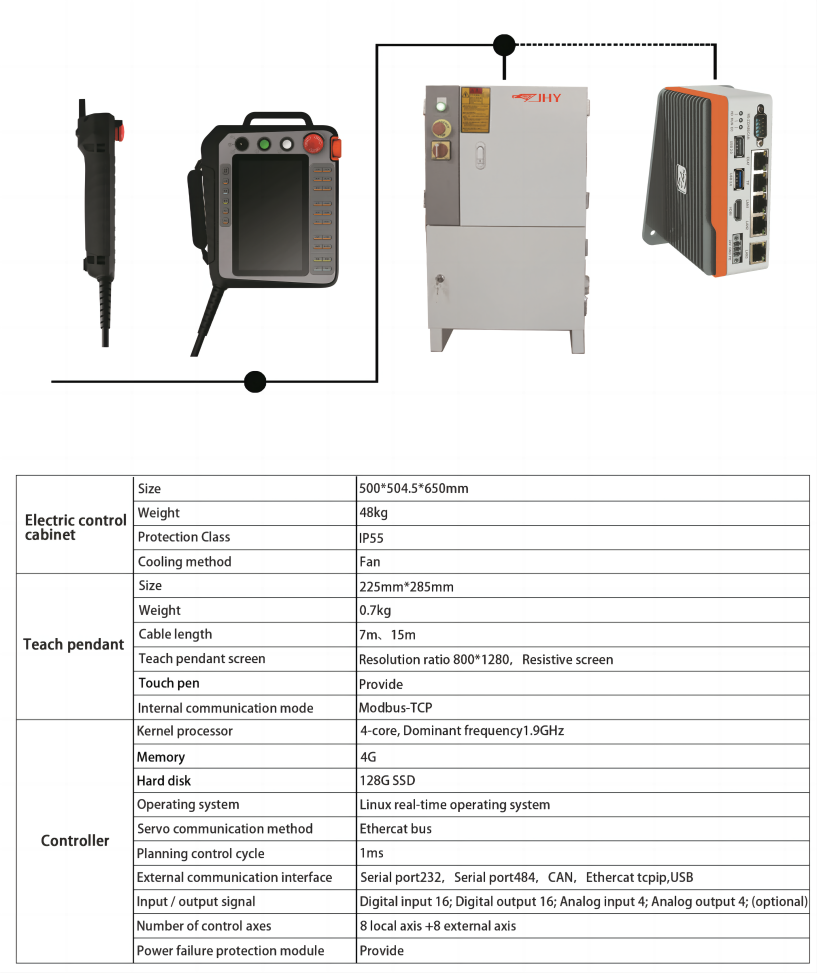

-JHY welding robot control system:

-Welding machine: :Aotai NBC350RL

-

It has three welding modes: low spatter, fast spot welding and constant pressure

- It can realize ultra-low spatter welding of 1~3mm carbon steel. The amount of welding spatter is reduced by 60%;

- The heat input is reduced by 10%~20%, and the welding of thin plates is easy to control and the deformation is small;

- The fully digital system realizes the precise control of the droplet transition and achieves continuous and stable welding quality;

- The soft switching inverter technology can improve the reliability of the whole machine and save energy and electricity;

- The fully digital high-precision wire feeding control system, the two-drive two-slave fully digital control wire feeding device with encoder can ensure the stability of wire feeding even if the external factors such as power supply voltage and wire feeding resistance change.

-Welding torch:

- Air-cooled with highly sensitive anti – collision device, greatly extend the service life of the torch

-Welding positioner & robot walking rail

- 1 axis,2 axis and 3 axis welding positioners are optional to choose. Payload and worktable size can be customized according to requirement.

- Robot walking rail can be made by customized according to customer’s requirement. length 3/6/9/12M.payload:500/1000KG

-The machine maintenance is simple and easy to operate, and the designed service life is more than 10 years

Paying Attention To Every Detail Makes JHY Robot Better

Write your message here and send it to us